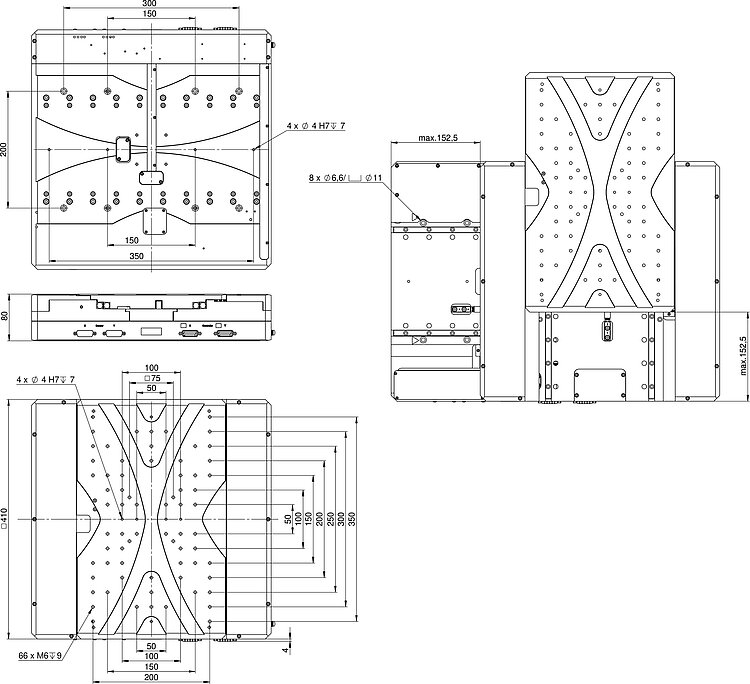

Precision XY stage; 2-phase stepper motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 45 mm/s × 45 mm/s maximum velocity; ball screw

L-741 Precision XY Stage

High Run-Out Accuracy and Stability, 305 × 305 mm Travel Range

- Travel range 305 mm × 305 mm (12'')

- Unidirectional repeatability to 0.05 µm

- Velocity to 90 mm/s

- 2-phase stepper motor or DC motors

- Incremental linear encoder with 1 nm resolution

- Rotary encoder with 20000 impulses/revolution

Highly accurate position measuring with incremental linear encoder

Noncontact optical linear encoders measure the position directly at the platform with the greatest accuracy. Nonlinearity, mechanical play or elastic deformation have no influence on the measurement. Optical limit and reference switches. More travel ranges on request.

Crossed roller guide

With crossed roller guides, the point contact of the balls in ball guides is replaced by line contact of the hardened rollers. Consequently, they are considerably stiffer and need less preload, which reduces friction and allows smoother running. Crossed roller guides are also distinguished by high guide accuracy and load capacity. Force-guided rolling element cages prevent cage creep.

Drive types

- 2-phase stepper motor for high torque even at low velocities and higher resolution

- DC motor for high velocity constancy, low vibration, and high velocities

Application fields

Medical industry. Laser cutting. Biotechnology. Measuring technology. Laser inscription.

Specifications

Specifications

| Motion | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

|---|---|---|---|---|---|---|---|

| Active axes | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | |

| Travel range in X | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | |

| Travel range in Y | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | |

| Maximum velocity in X, unloaded | 45 mm/s | 45 mm/s | 45 mm/s | 50 mm/s | 50 mm/s | 90 mm/s | |

| Maximum velocity in Y, unloaded | 45 mm/s | 45 mm/s | 45 mm/s | 50 mm/s | 50 mm/s | 90 mm/s | |

| Orthogonality | ± 96 µrad | ± 96 µrad | ± 96 µrad | ± 96 µrad | ± 96 µrad | ± 96 µrad | typ. |

| Straightness error E_YX (straightness) | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | typ. |

| Straightness error E_ZX (flatness) | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | typ. |

| Angular error E_AY (pitch) | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | typ. |

| Angular error E_BX (pitch) | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | typ. |

| Angular error E_CX (yaw) | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | typ. |

| Angular error E_CY (yaw) | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | typ. |

| Positioning | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Minimum incremental motion in X | 1 µm | 0.05 µm | 0.05 µm | 0.1 µm | 0.5 µm | 0.8 µm | typ. |

| Minimum incremental motion in Y | 1 µm | 0.05 µm | 0.05 µm | 0.1 µm | 0.5 µm | 0.8 µm | typ. |

| Unidirectional repeatability in X | ± 0.05 µm | ± 0.025 µm | ± 0.025 µm | ± 0.05 µm | ± 0.25 µm | ± 0.4 µm | typ. |

| Unidirectional repeatability in Y | ± 0.05 µm | ± 0.025 µm | ± 0.025 µm | ± 0.05 µm | ± 0.25 µm | ± 0.4 µm | typ. |

| Bidirectional repeatability in X | 5 µm | 1 µm | 1 µm | 1 µm | 1 µm | 5 µm | typ. |

| Bidirectional repeatability in Y | 5 µm | 1 µm | 1 µm | 1 µm | 1 µm | 5 µm | typ. |

| Reference switch | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | |

| Reference switch repeatability | 1 µm | 1 µm | 1 µm | 1 µm | 1 µm | 1 µm | |

| Limit switches | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | |

| Integrated sensor | — | Incremental linear encoder | Incremental linear encoder | Incremental linear encoder | Incremental linear encoder | Incremental rotary encoder | |

| Sensor signal | — | Sin/cos, 1 V peak-to-peak | A/B quadrature, RS-422 | Sin/cos, 1 V peak-to-peak | A/B quadrature, RS-422 | A/B quadrature, RS-422 | |

| Sensor signal period | — | 20 µm | — | 20 µm | — | — | |

| Sensor resolution | — | 1 nm | 10 nm | 1 nm | 10 nm | — | |

| Sensor resolution | — | — | — | — | — | 20000 Cts./rev. | |

| Drive properties | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Drive type | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | DC motor | DC motor | DC motor | |

| Operating voltage | 24 V | 24 V | 24 V | 24 V | 24 V | 24 V | |

| Nominal current, RMS | 1.2 A | 1.2 A | 1.2 A | 3.9 A | 3.9 A | 3.9 A | typ. |

| Motor resolution | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | — | — | — | |

| Drive force in X | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | typ. |

| Drive force in Y | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | typ. |

| Resistance phase-phase | 3.4 Ω | 3.4 Ω | 3.4 Ω | 0.62 Ω | 0.62 Ω | 0.62 Ω | typ. |

| Mechanical properties | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Permissible push force in Z | 200 N | 200 N | 200 N | 200 N | 200 N | 200 N | max. |

| Permissible torque in θX | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | max. |

| Permissible torque in θY | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | max. |

| Permissible torque in θZ | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | max. |

| Moved mass in X, unloaded | 19900 g | 19900 g | 19900 g | 20200 g | 20200 g | 20200 g | |

| Moved mass in Y, unloaded | 6100 g | 6100 g | 6100 g | 6100 g | 6100 g | 6100 g | |

| Drive screw type | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | |

| Drive screw pitch | 2 mm | 2 mm | 2 mm | 2 mm | 2 mm | 2 mm | |

| Guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | |

| Overall mass | 27500 g | 27500 g | 27500 g | 28000 g | 28000 g | 28000 g | |

| Material | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | |

| Miscellaneous | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | |

| Connector | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | |

| Sensor connector | — | 2 × D-sub 15 (f) | — | 2 × D-sub 15 (f) | — | — | |

| Recommended controllers/drivers | G-901.R319 G-902.R2E001 C-663.12, C-885 with C-663.12C885 ACS modular controller | G-901.R319 G-902.R2E001 ACS modular controller | G-901.R319 G-902.R2E001 C-663.12, C-885 with C-663.12C885 ACS modular controller | G-901.R319 G-902.R2E001 ACS modular controller | G-901.R319 G-902.R2E001 C-863.12, C-885 with C-863.20C885 ACS modular controller | G-901.R319 G-902.R2E001 C-863.12, C-885 with C-863.20C885 ACS modular controller |

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Documentation

User Manual MP184

L-741 / V-741 Precision XY Stage

3D Models

L-741 3-D model

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Precision XY stage; 2-phase stepper motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 45 mm/s × 45 mm/s maximum velocity; ball screw; incremental linear encoder, 20 µm sensor signal period, sin/cos, 1 V peak-peak

Precision XY stage; 2-phase stepper motor; 305 mm x 305 mm travel range (X × Y); 200 N load capacity; 45 mm/s × 45 mm/s maximum velocity; ball screw; incremental linear encoder, 10 nm sensor resolution, A/B quadrature, RS-422

Precision XY stage; DC motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 50 mm/s × 50 mm/s maximum velocity; ball screw; incremental linear encoder, 20 µm sensor signal period, sin/cos, 1 V peak-peak

Precision XY stage; DC motor; 305 mm x 305 mm travel range (X × Y); 200 N load capacity; 50 mm/s × 50 mm/s maximum velocity; ball screw; incremental linear encoder, 10 nm sensor resolution, A/B quadrature, RS-422

Precision XY stage; DC motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 90 mm/s × 90 mm/s maximum velocity; ball screw; incremental rotary encoder, 20000 counts/rev sensor resolution, A/B quadrature, RS-422

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

Classical Guiding Systems

Positioners with travel ranges from several millimeters to one meter usually utilize traditional mechanical guide components such as ball bearings.

Incremental Sensors

PI uses incremental measurement systems for longer travel ranges, starting from approximately one millimeter. These sensors, which in most cases are optical sensors, achieve position resolution down to the picometer range.

Hexapods and SpaceFAB

Hexapods are systems for moving and positioning loads in six degrees of freedom, in three translational and three rotational axes.

Rotating Electric Motors

Rotating electric motors such as DC or stepper motors are used in connection with screw or worm drives.

Applications

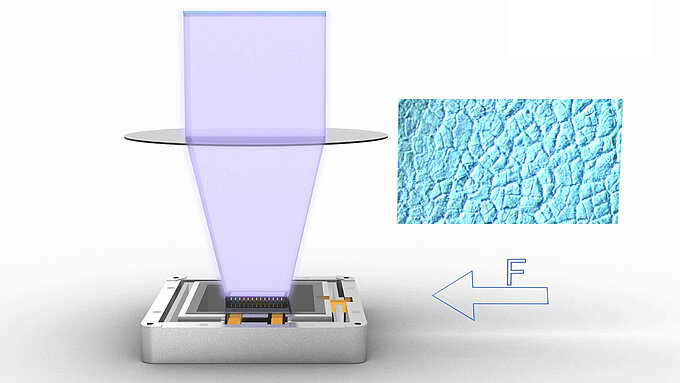

Genome Sequencing

Be it in medicine, forensics, or genetics - the genome is the key to new insights for numerous questions. The method known as sequencing-by-synthesis, which used to decipher the genome, has become faster and more precise since it was first developed — the cost has decreased, respectively. The positioning techniques employed in the microscope systems used for this purpose have also contributed to...

Video Endoscopy

Modern medical technology focuses on developing therapies that cause as little discomfort to patients as possible. Endoscopes that allow minimally invasive surgery, make an important contribution to this, for example, in laparoscopy. Especially during medical interventions, the demand for focused and detailed image information is of the highest priority in order to achieve the best possible...

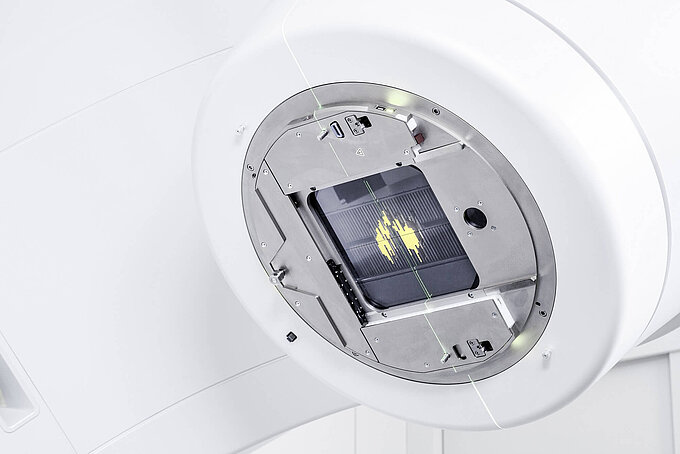

Adaptive Diaphragm Positioning

In radiation therapy, the individual leaves are adjusted so that the healthy tissue offers the optimum protection from the radiation.

Image Stabilization

Fast, piezo-based scanners operate with the necessary velocities in the video frequency range for image stabilization and microscanning.

Pipetting

Piezomotors are suited for pipetting with small devices and sample separations and are able to move the pipettes in the vertical direction.

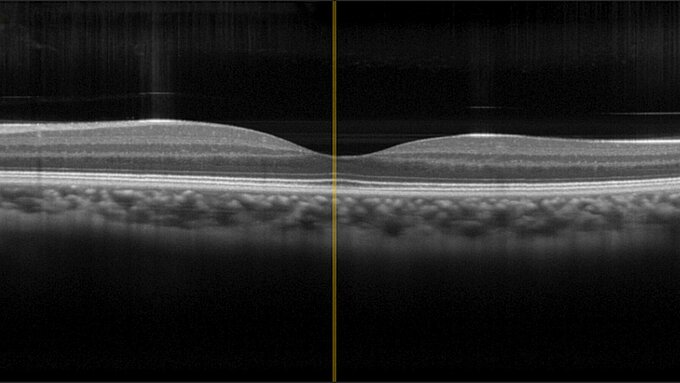

Optical Coherence Tomography

Piezo actuators and drives, e.g., PILine® OEM motors, ensure the high precision and position stability required for optical coherence tomography (OCT).

Magnetic Resonance Imaging

Piezo drives are well suited for magnetic resonance therapy, because they are not influenced by strong magnetic fields.

Refractive Surgery

In refractive surgery, high-precision positioning and motion control of the laser are decisive for good results. Piezo-driven stages and tip/tilt mirror systems offer the requested precision, are dynamic and fast and thus additionally help to reduce the treatment time.